Proper operation of the

Automatic Coating System is essential to achieve optimal coating results. Before starting the system, it is necessary to conduct a thorough inspection of all components. Check the coating material supply system to ensure that there is an adequate amount of coating material and that the supply lines are free from blockages or leaks. Inspect the conveyor system to make sure it is clean and running smoothly, as any debris or mechanical issues can affect the movement of substrates through the coating process.

When setting up the coating parameters, refer to the product specifications and coating requirements. Use the control panel to adjust parameters such as coating thickness, spray speed, and drying time according to the specific substrate and coating material being used. It is important to conduct test runs with a few sample substrates to fine-tune the parameters and ensure that the coating quality meets the desired standards.

During the coating process, continuously monitor the system's operation. Keep an eye on the coating application unit to ensure that the coating is being applied evenly and without any irregularities. Check the conveyor speed and substrate positioning to ensure that each substrate is properly coated. If any issues are detected, such as uneven coating or substrate jams, stop the system immediately and address the problem before continuing.

After the coating operation is completed, proper shutdown procedures should be followed. Turn off the power supply to the system and clean the coating application unit and surrounding areas to prevent the buildup of dried coating material, which can affect future coating quality. Dispose of any waste coating material and cleaning solvents in accordance with environmental regulations.

Regular maintenance is crucial for the long-term performance and reliability of the Automatic Coating System. Establish a maintenance schedule that includes routine inspections, cleaning, and component replacements. Clean the filters in the coating application unit and the ventilation system regularly to maintain proper airflow and prevent clogging, which can reduce the efficiency of the coating process.

Inspect and replace worn or damaged components such as spraying nozzles, conveyor belts, and seals in a timely manner. Lubricate moving parts according to the manufacturer's recommendations to reduce friction and extend the lifespan of the components. Additionally, update the system's software and firmware as needed to ensure that it is operating with the latest features and performance enhancements.

By following these operation and maintenance guidelines, users can maximize the performance and lifespan of their

Automatic Coating System, ensuring consistent and high-quality coating results for their products.

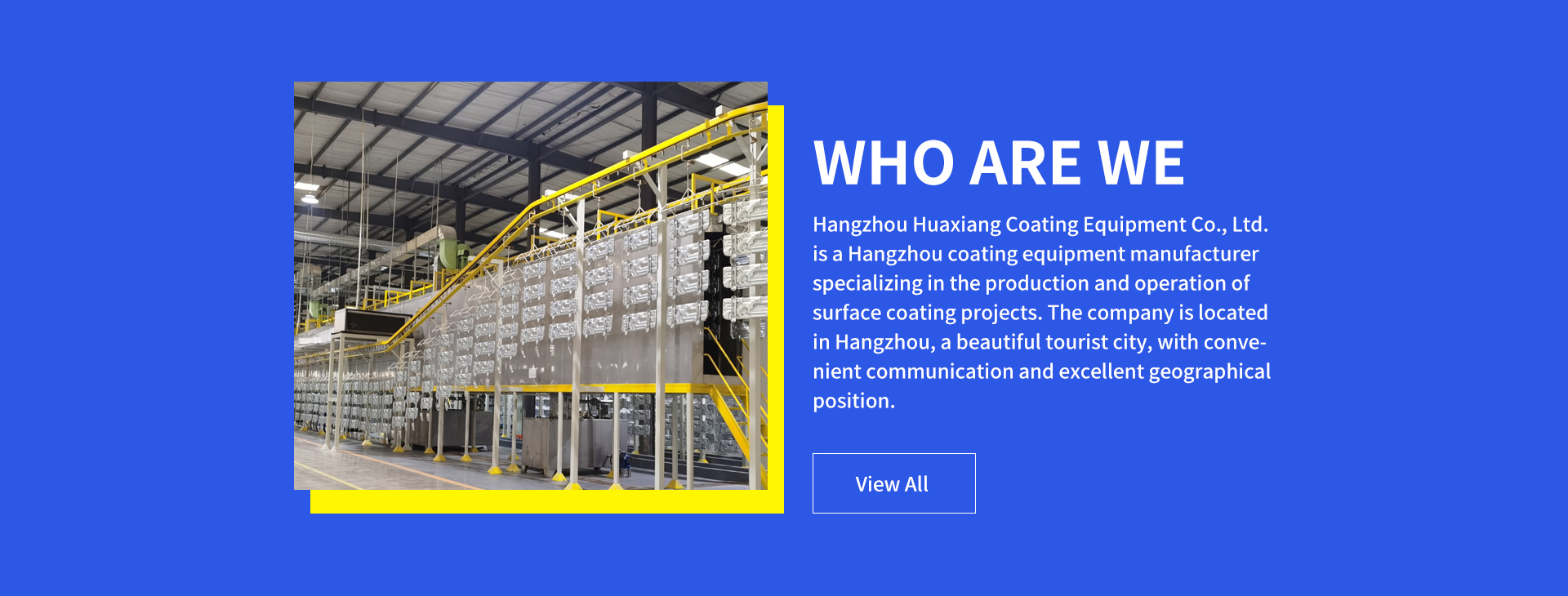

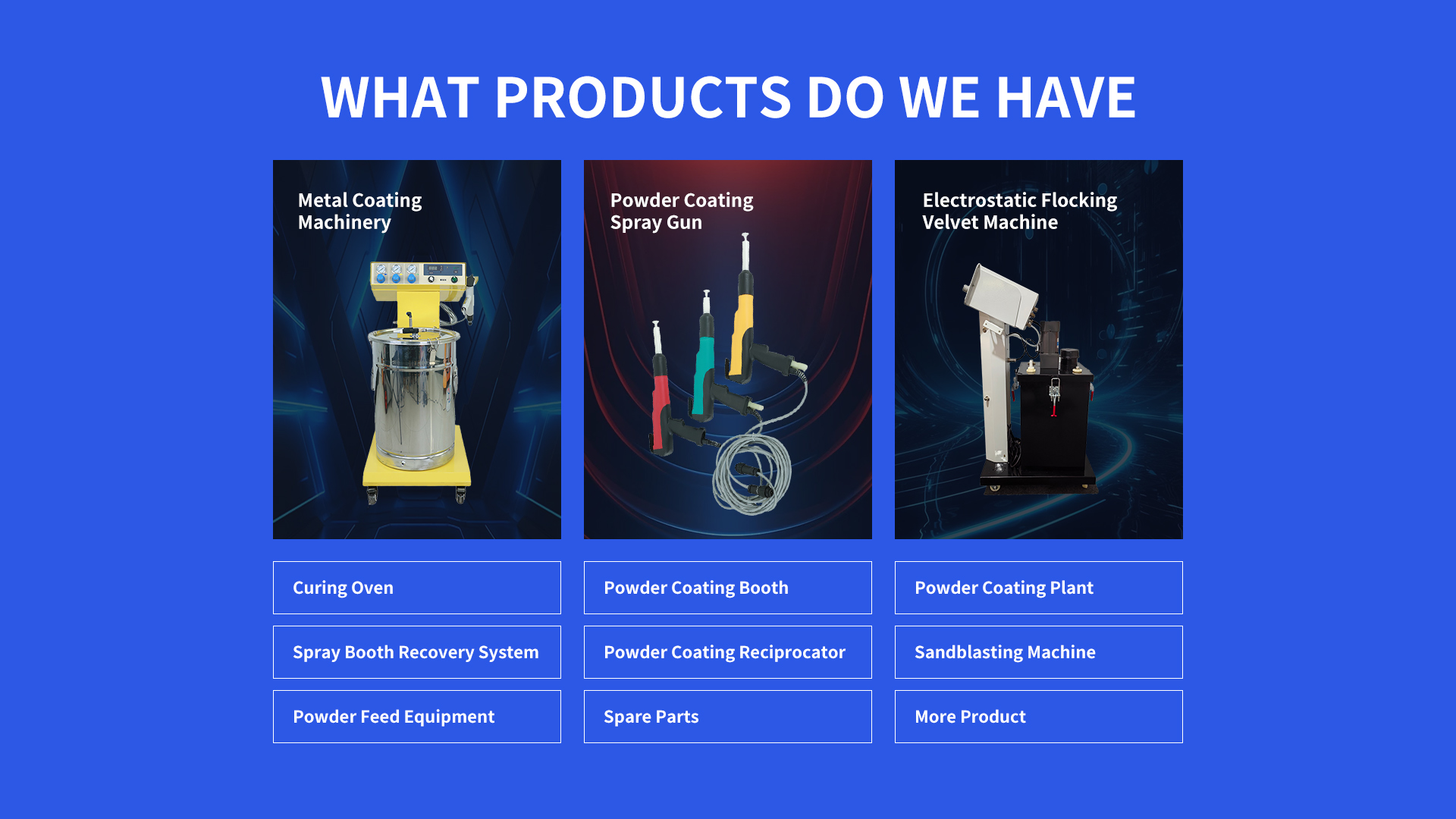

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com